Club Meeting: 2 March 2022

Report by: John Young

With a demonstrator away, Garry kindly jumped in at the last minute to give us a great demo.

Tonight Garry showed us how to make Tubes. A fun project, in which warping, shrinkage and movement are welcomed to create unique pieces. The tubes also lend themselves to well to embellishment, carving, pyrography etc.

Before beginning, Gary spoke about the importance of understanding how the grain will influence movement of the piece as it dries. For example, a tube cut from end grain might warp very little, while a cross grain piece will offer much more movement.

Gary started with a long piece of wet Banksia approx 70mm in cross section. Wet wood is of course necessary to get the movement and warping of the tubes as they dry.

Bark can be left on or removed. If you plan to leave bark on at the top, it is important to cut down and away from the bark rather then towards it, as this lessens the chance of accidentally removing the bark.

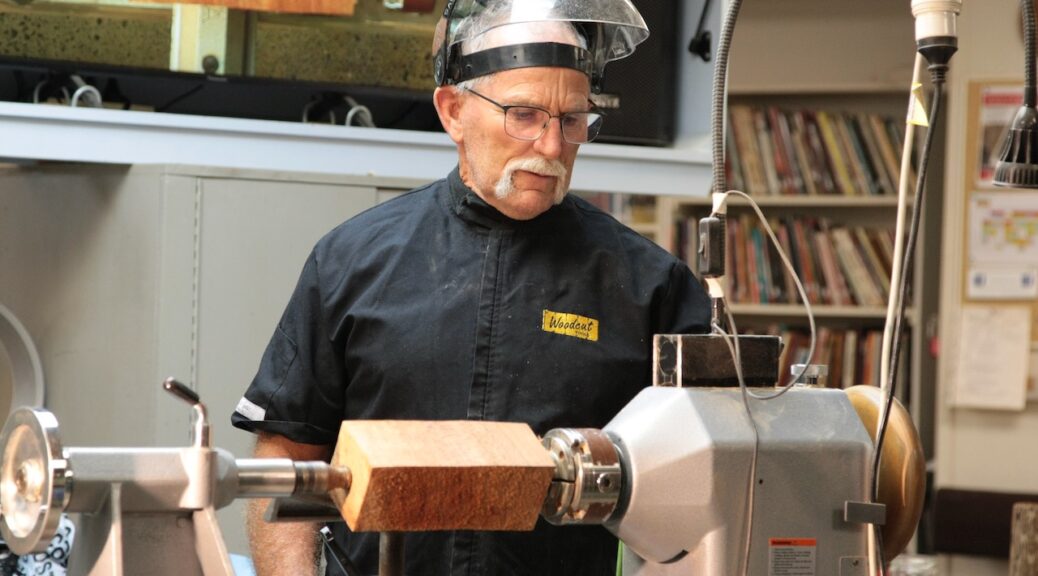

Firstly, the blank was mounted between centers and rounded.

A 50mm tenon was cut at the base. A slightly larger tenon is cut than usual as we are dealing with wet wood which compresses more.

The blank was then remounted into a 50mm chuck. The tail stock can be brought up to help center the blank.

After mounting, a Forstner bit with an extension is mounted in the tail stock. Gary used a 44mm forstner bit for this demo, but you can use any size you like, you will just have to create a matching size mandrel for it.

Mark how deep you want to drill, taking care to leave enough (i.e. 10mm approx) on the bottom for parting off later.

Gary then drilled out the center, taking care to remove the shavings frequently to prevent jamming.

Dick suggested not pulling the forstner bit out all the way, when removing shavings. This prevents the entry point getting damaged or chipped every time you re-enter with the forstner bit.

Once the tube was hollowed, Gary removed it from the chuck and mounted a pre-made wooden mandrel. The mandrel is a large dowel cut to roughly the same width as the hole in your tube.

The tube was then be fitted over the mandrel, with the tail stock brought up for support. If the fitting is lose, tape can be wrapped around the mandrel to provide a snug fit.

Be sure to get a nice firm, centered fit. If the tube is off-center, the wall thickness of your tube will become uneven.

Once it was firmly on, Gary reduced the wall thickness to his desired amount.

Important to note the tube should be completed in one go, without removing it from the mandrel. It can warp very quickly and may not recenter again once you have removed it.

Once he was happy with its final thickness, Gary parted off the base, cutting a slight concave in the bottom, to allow the tube to stand flat.

Sanding can be done before parting off, or when the wood has completely dried. Some woods are better to sand once wood is completely dry.

Thanks Gary for stepping in at the last minute and giving a great demo.

https://sawg.org.nz/sawg/wp-content/uploads/2011/09/Tubes.pdf