Club Meeting: 14 August 2024

Report by Graeme Mackay

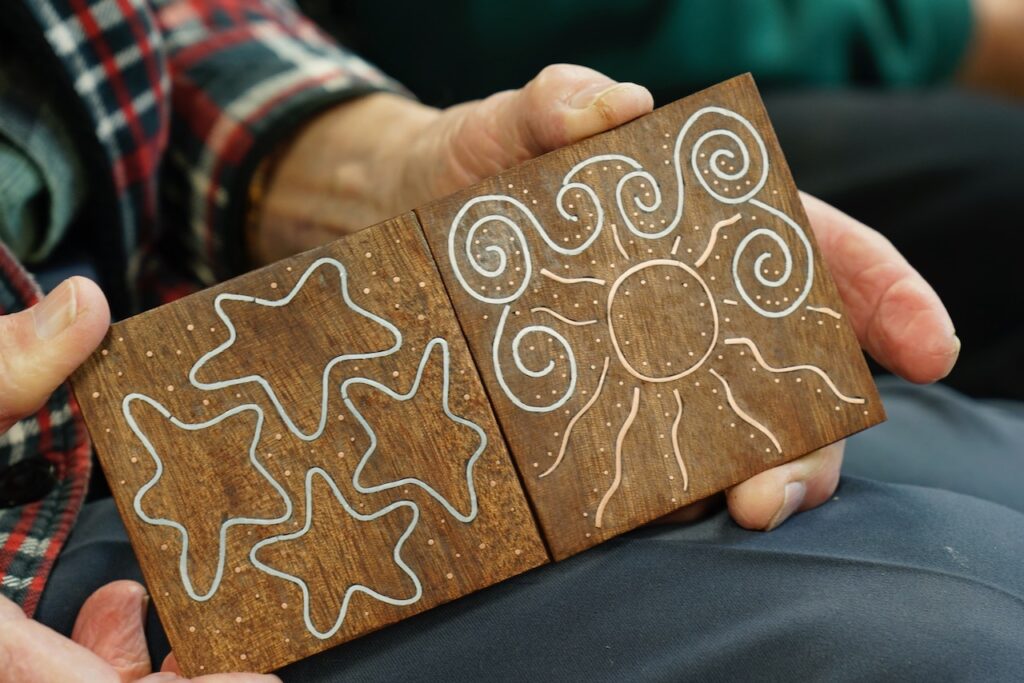

Janet provided an interesting and colourful way of using other materials such as metal wire for inlays into wood.

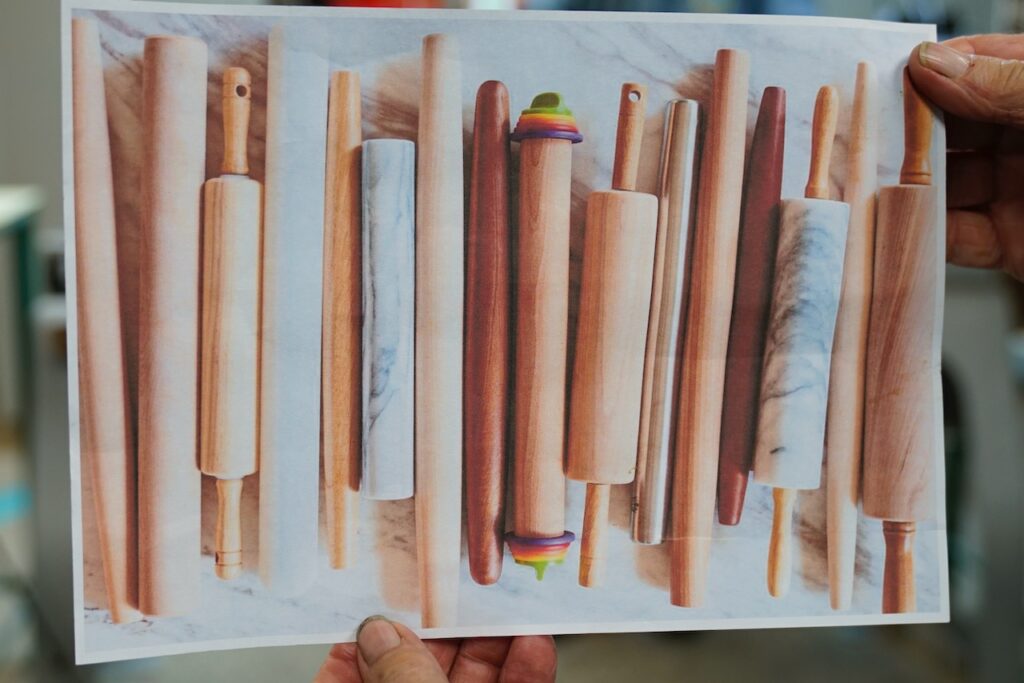

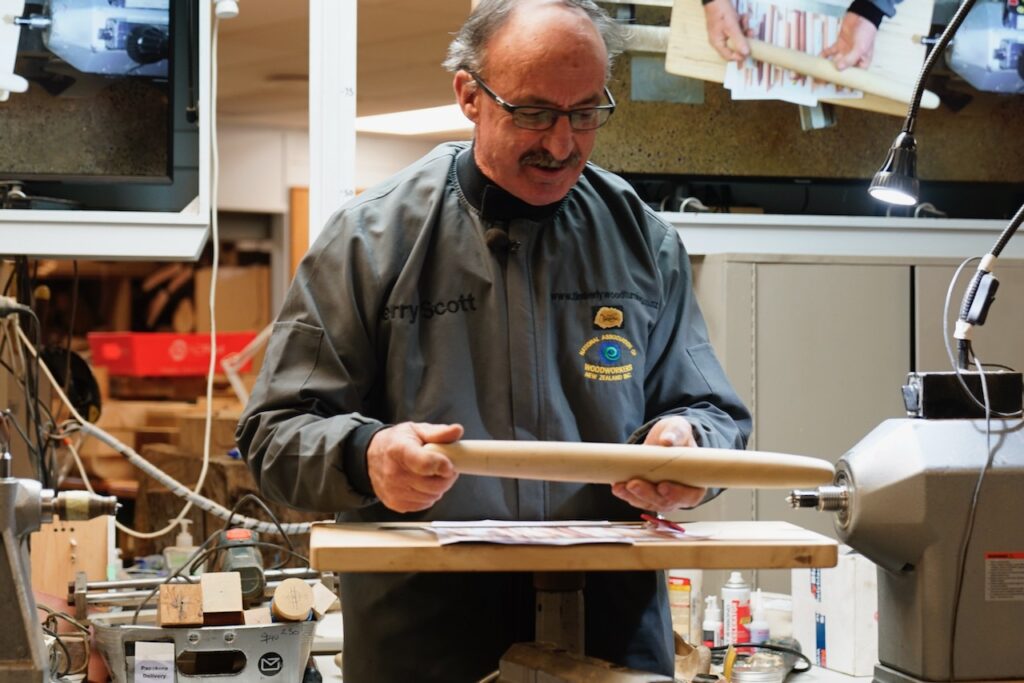

The sections and techniques were clearly defined with examples, demonstration pieces and a whole array of tips and assists. The overall goal being to insert metal wire into turned and carved Wood Craft pieces. And as the demonstration proceeded, Janet highlighted an arrangement of uses that this form of embellishment can be used. Janet showed design layouts and ways in which you apply your own particular application skill level.

Cloisonné:

Janet showed aluminum cloisonné wire that is rectangular in shape. Working from standard sizes and commercial based products. Also she showed how to use round copper wire using the same techniques.

Channeling:

Carving channels to fit in wire is an important part of the wire application and one that needs much practice and patience. Clean grooves are a constant for this and the laying process. Carving a channel deep enough that 1mm of the wire protrudes from the surface of the wood. Remember to keep your wood shaving for later.

Wire fixing

Thin CA glue was used to dampen the channels and then wire inserted. Then use sawdust to fill any gaps where your channel might have got a bit wide. Apply CA again and allow it to totally dry.

Sanding:

Speed is not your friend when getting your wood and wire to a smooth even surface. Do not put the wood back on the lathe to skim or use a bench top sander. The friction from the fast movement and heat buildup will soften your CA glue and the wire and bits of wire will pop out. Use a hand held mouse sander or a dremel style drum sander first. Then hand sand down to 400 to 600 grit. Do not use a Beal buff system to polish as it will reheat the wire. Any oil or wax is fine to use.