Club Meeting: 14 April 2021

Report by: John Young

Dave shows us all his inside tips and tricks to make an elegant lidded box.

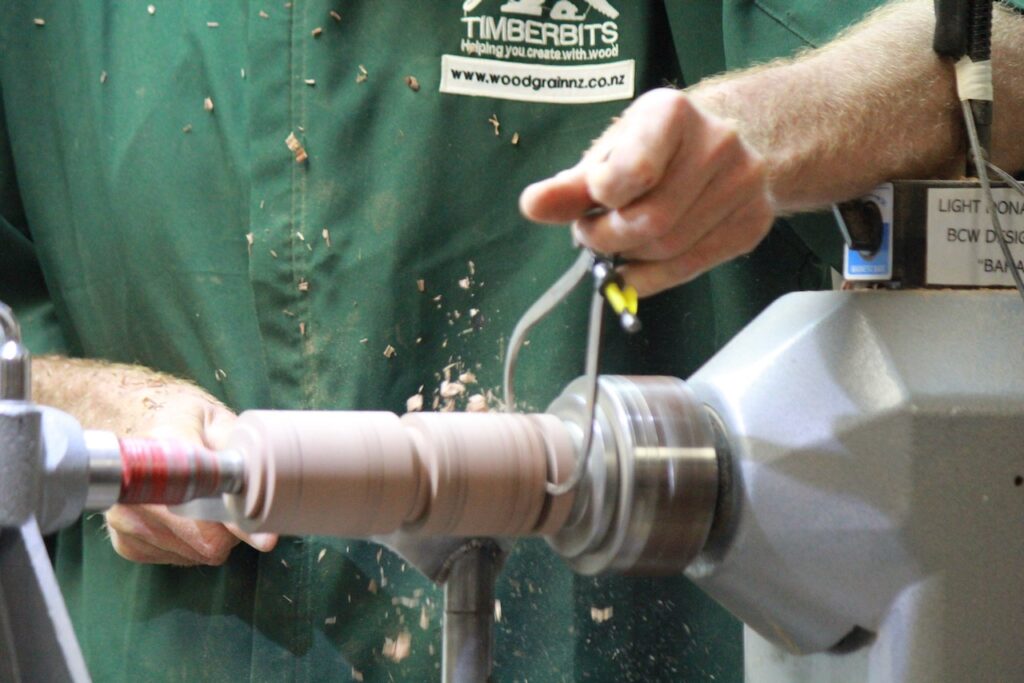

He starts by mounting a small block of Pohutakawa between centers and turning it round.

Spigots are made on both ends to fit a 50mm chuck.

After remounting in a chuck, a parting tool is used cut the base (30mm wide).

A bowl or spindle gouge can now be used to shape a nice outside curve of the box.

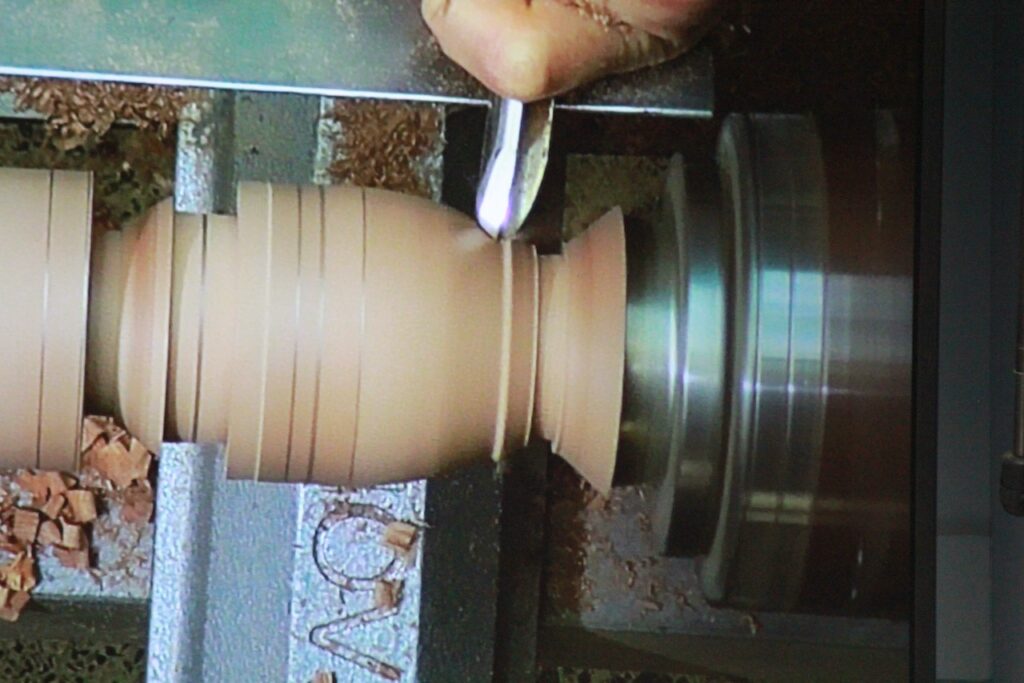

A parting chisel is used to cut the sleeve, which will later fit inside the lid.

A 50mm chuck is then fitted into the tail stock (via an adapter). This chuck is used to hold the lid while it is parted from the base. This will help keep the lid perfectly alighted.

The lid is set aside, while the bottom is hollowed out. First with a forstner bit, then a hollowing tool to achieve a nice interior curve. The interior is sanded, coated with superglue and burnished with beeswax. The superglue will provide a tough, durable finish inside.

The lid is now mounted and hollowed inside with various bowl gouges. Check the fit of the lid to the bottom.

If the fit is good, the interior of the lid can then be sanded, textured and finished in the same way as the bottom. The lid is set aside.

The bottom is then remounted in the headstock, with the lid mounted in the tail stock chuck. Both pieces are pushed together. While spinning, a point tool is used to mark both sides of the join to help hide it. Lines are burnt into the grooves with a piece of thin wire.

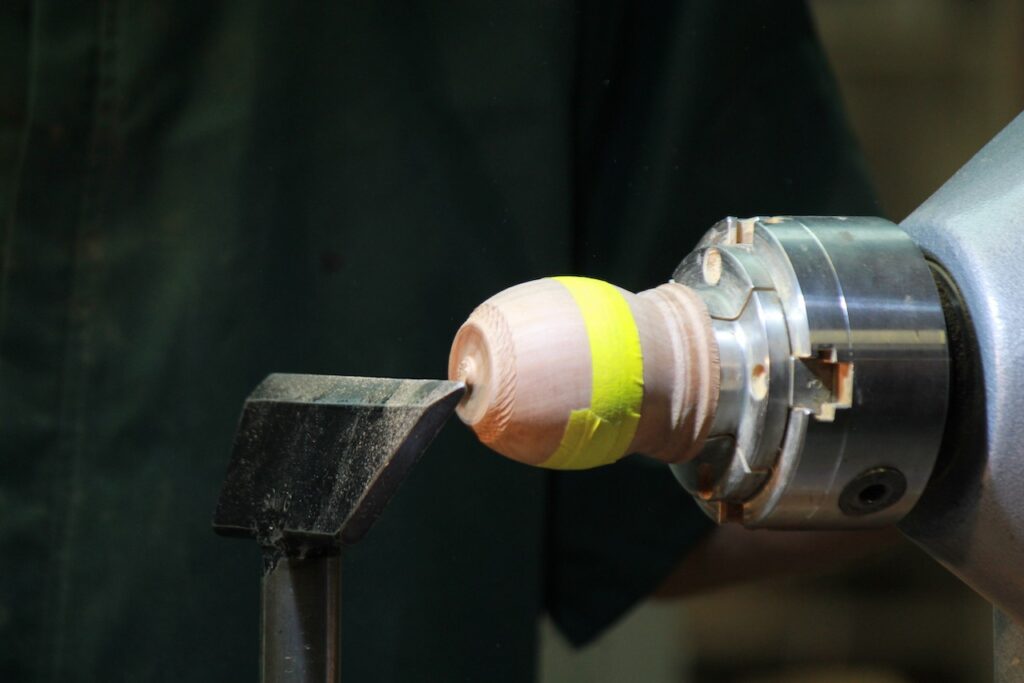

Lid is removed from its chuck and jammed onto bottom so it can be tidied up.

Lid exterior can now be textured, sanded and finished.

Bottom is removed from chuck, mounted in a jam chuck and tidied up.

After sanding, a spray polyurethane is used to achieve a pleasing finish.

Thanks Dave for another excellent demo, which was well received.