Photos by Strett Nicolson & Ross Johnson

Photos by Strett Nicolson & Ross Johnson

Photos by Strett Nicolson & Ross Johnson

Club Meeting 20 February 2019

Reported by Murray Wilton

Photos Ross Johnson

Strett wanted a new challenge, to move out of his comfort zone, so he chose a fairly complex bowl-turning project he found in a magazine. Regrettably, when he came to start the project he couldn’t find the recipe and had to rely on his memory, which must be quite good because he managed the presentation with suitable aplomb.

If newer members and beginners, including the reporter, were puzzled by some of what was going on, at least they learned some valuable lessons on alternative ways to mount their work. In his efforts to avoid mounting on a faceplate with inevitable screw holes that are hard to eliminate, Strett turned to the age-old glue-and- paper-gasket method. First he made an mdf mount, screwed with self-tapping wood-screws to a faceplate and rounded to about 200 mm diameter.

The alternative of a expanding jaws into a hole in the MDF was discussed, the audience questioned the reliability of using mdf in this way, as it is likely to delaminate,

For this project the faceplate timber and the work piece must be perfectly flat, so ensure the faces are flat before proceeding. Remove the mdf or timber mount from the faceplate. Use a paper gasket (120 gsm copy paper best as newsprint will soak up the glue) and apply glue to each side. Strett uses Aquadhere glue. Bring the faceplate timber and the work piece together and apply pressure in a vice or clamp of some sort and leave to dry overnight.

Use a centre-finder to locate the centre of the blank. Bring the tailstock live centre up against it. Squeeze the blank and mount against the chuck and, working gently so that it will stay in place, round it off. All this so screw holes are not required in the work piece.

Locate the mount in a chuck using the spigot cut earlier and begin hollowing out the bowl, leaving an outside flat edge of 5mm. Ensure the hollowing leaves at least 6 to 7 mm at the bottom. Use a contour gauge (available from Machinery Co.) to measure the inside shape of the bowl and make a template. (Some turners use the template method for all their bowl-turning as it removes guesswork.) Remove bowl from the paper gasket and remount on another faceplate blank as above. When dry mount on a chuck and start shaping the outside of the bowl, frequently checking with the template to ensure the bowl sides are of even thickness.

Finding a nail in the bowl led to a slight hiatus as various audience members gave advice on dental extraction procedures to eliminate the nail.

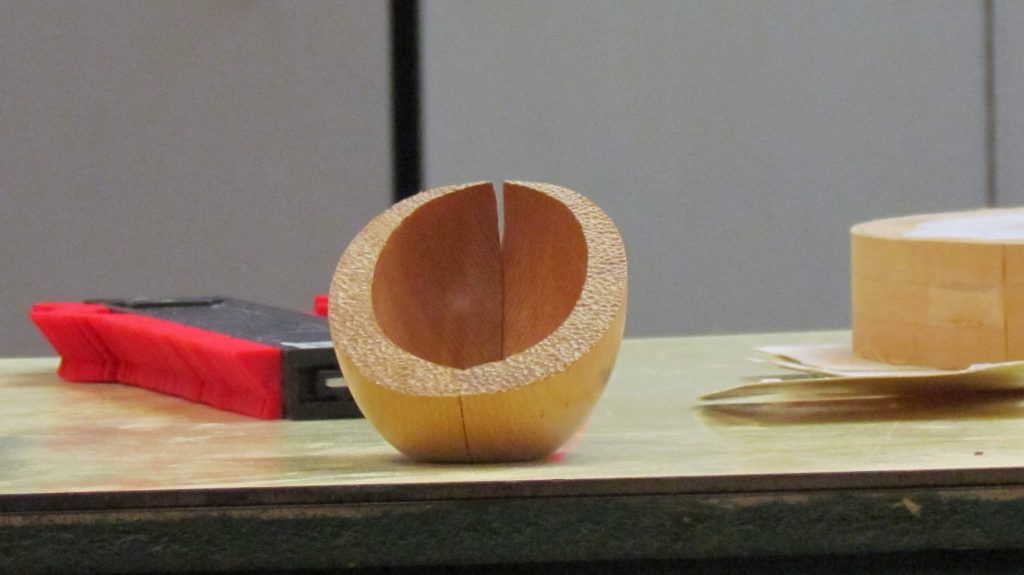

Once the correct shape is achieved Strett completes all finishing work before splitting the bowl off the faceplate. He then cuts the bowl in half with a bandsaw and re-glues to form an almond-shaped offset bowl.

Great demo, although it left some of the audience baffled by science, smoke and mirrors.

Club Meeting: 13 February 2019

Report; Bill Alden

Photos: Ross Johnson

Terry used a square piece of wood and found centre using the usual cross lines centre was punched with a Phillips screwdriver which allows the 7 ½ mm drill to not wander. This is then mounted on a screw chuck.

Terry then made the made sure that the tool rest had no nicks in it he used a sanding pad and polish.

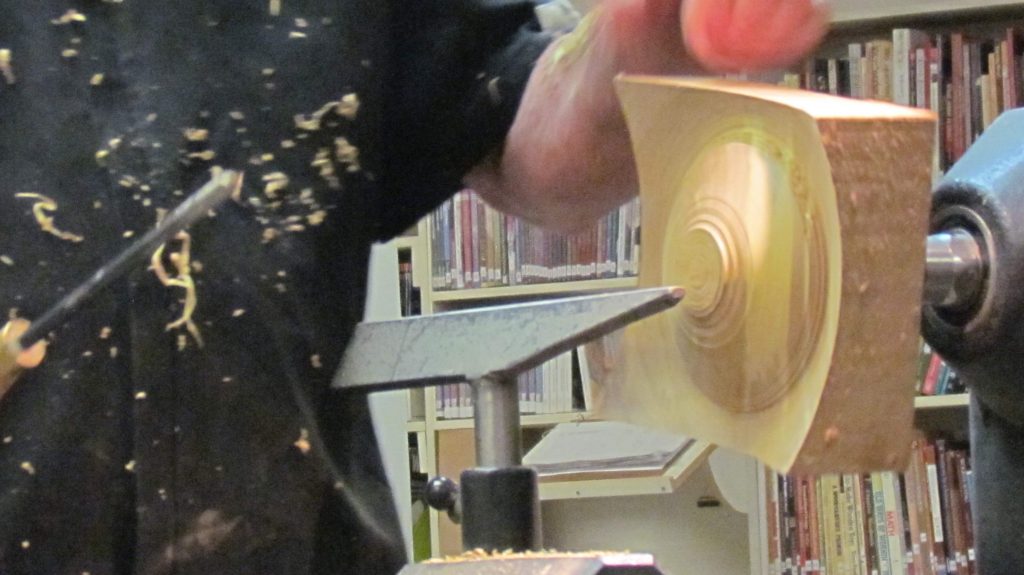

The drop wings are formed first and a 50 mm spigot is formed in the middle to reverse chuck. If desired make sure that the piece will sit on the wings not on the base. The chisel used was a 10 mm bowl gouge with swept back wings this is advisable so that the chisel can be turned without catching the bowl in the middle when doing the underside of the wings.

The curves can be checked by laying a glue stick across it and seeing if there are any gaps. If planning to do 3 feet use a larger 75 mm chuck to make a larger ring the bottom of the bowl, and carve feet when finished. The centre of the spigot was marked with the long point of skew chisel for ease of centring when turning the foot of the bowl

Draw a series of lines approximately 4 mm apart from the base of the bowl, vertical gridlines can then be put in using the indexing feature of the lathe. These lines will be used as guides when finally decorating the bowl.

Reverse the bowl onto a 50 mm chuck and cut the wings from the centre out, hollow the bowl and cut a shoulder in order to fully rub the bevel. Form a nice curve so the wings flow into the bowl.

Terry then showed us various ways of decorating the bowl, the inside could have a series of beads to simulate a splash and other decoration to make waves in the wings, using a mini Arbortec to carve the lines. Terry then sanded up to 240 grit on a sanding mandrel.

Other decorations can be done with a wire brush on a drill, a Dremel or a pyrography machine. Using a knife edge on the Burnmaster, Terry showed us how to highlight the grain lines in the wood. Colour can then be applied (Terry prefers black) he uses acrylic paint, Kiwi boot polish or gilders paste. Terry then showed us how he carved feet using a mini Arbortec.

Thank you once again Terry for a very informative and interesting demonstration.

Club Meeting: 12 December 2018

Report by Murray Wilton

President (not for life) Ian Connelly was the last presenter for 2018. He chose a challenging and difficult subject, German ring-turning, about which very little is known. In fact, if you Google it you will get few hits unless you go to a German site (<www.reifentiere.de>) and have enough German language to interpret what you see. However, the associated YouTube videos are so shielded by the turner that it’s almost impossible to see what’s going on. Ian’s presentation was inspired by a German ring-turning inspired piece he won at auction at this year’s Symposium, a New Zealand fantail, turned and carved from a bowl round by expert Derek Weidman. With little to follow in the way of plans or instructions, Ian worked out the detail for himself.

Displaying his turning skills, Ian started with a 250 X 250 mm square of kahikatea, not even rounded with the bandsaw. As he said, he could have cut the corners off, but intrepid and skilled turners don’t need to do that. Ian reminded novice turners to ensure the mounting screw is tight up against the flange and firmly and evenly snug against the chuck. If not it will be moved by centrifugal force and nothing will work after that.

Using a large bowl gouge (Ian showed us an even more massive tool but didn’t use that one) and running the lathe at 600 rpm, Ian transformed a perfect square to a round in minutes, rounding off the inner and outer edges to make the next steps safer. Next a wedge is removed from the round, using a band saw, and a profile of a kiwi is glued to one face. The extremities of the kiwi shape (feet, body curves, beak) are marked on the round and then turning from the face side with a bowl gouge begins. Frequent stops are needed to ensure that the shape is being correctly followed.

The completed kiwi is then cut out from the round and can be finished with the dremel or carving tools. Alternatively the kiwi can be left 2-dimensional and used as hangings on the Christmas tree or other ornamental possibilities. Multiple kiwi or other animals or shapes can be turned from one round.

Definitely something quite different and certainly a challenge.

Club Meeting: 5 Dec 2018

Report by Graeme Mackay

Dick’s pencil boxes demonstration: This exercise was taken from an AAW project that was based on Beth Ireland’s boxes. The process is that the box making system ends up with a pencil looking like a pencil case. Dick started the demo with a history of lead pencils i.e. those with graphite in them in. Then a discourse about the colours that pencils came in.

The base: A cylinder, about 200 mm long is made with two jam chucks it is cleaned and then a parting is taken around 60 mm from one end.

A Dick V tip: When parting off a piece, remember to keep the gap and do not let the tool jam.

The next process is started with hollowing by way of Forstner bit or bits if you are precise. A piece of measured tape on Forstner bit provides a depth check. The second Forstner bit opens the hole further. The second part of the hole is continued with an extension on the Jacobs chuck.

Another Dick B tip: keep to speed down when using Forstner bit and check the actual width of the piece.

The lip at the top of the long section allows for fitting the pencil top onto the box base. Remember, the lip on the box head is made to fit the base lip. Similarly, a hole check on box top depth is required. Measure and make the lip fit in a close manner and this is done while leaving the box top in the chuck.

The pencil faces: Dick brought out his cleverly fashioned jig. A boxlike structure that is attached to the frame of the lathe. After some adjustment, fiddling, shifting around, the Router was used to clean off the six faces of the pencil. Some measuring and judging is required. The box is relatively simple and is technically only a guide for the router. It is simply one of the ways in producing the six sides of the pencil – all hopefully matched even and appropriate looking.

Back to the top i.e. the sharp end that that has imitation graphite in it. The lip is mark with Vernier callipers and cut down with a standard skew. It is hoped that you have remembered to leave sufficient thickness to accommodate the flat faces and that they join into a new top.

The finishing touch: The bead lines highlight the end of the pencil in the piece that holds your eraser. Texturing highlights these beads provides a differentiation to the pencil part and hopefully shows up in its glory, with some clean edges. This part of the process is achieved by putting the top of the box/pencil case onto a cylinder mandrel. Holding the box top on with the stem centres will assist safety and avoid any mishaps.

Colouring helps highlight faces, eraser frame and eraser itself. The sharp end of the pen is highlighted by colour or even just a dark felt -tip.

This is a standard box process with some interesting features. The avoiding confusion is easy, just go onto the site, and follow the box making plan.

Tip

The best tip once you enter this process is

measure, measure again, and check that measurement.

Graeme Mackay

December 2018

Club meeting 28 November 2018

Report by Earl Culham

Garry chose to demonstrate the turning of a Christmas decoration (in his words a doo da) in the shape if a lantern with finials top and bottom.

Using a cube of kauri 50×50, but of course you may use any size or material you wish; Garry marked the centres on all sides. Mount in a 50mm chuck with the end grain towards the head and tail stock. Drill a 7mm hole thru the cube to take the finials. Garry then used a 13mm countersink bit to provide a seat for the finials when they are glued in.

Reposition the cube in the chuck and drill out the four sides using a 35mm forstner bit. Drill half way through, rotate the cube and drill from the other side to complete the hole, sand the hole to a neat finish as you go.

Once the four sides are drilled, the edges have to be rounded. Gary used his own adaption to hold the cube by using his pen mandrel threaded through the finial holes. He added a couple of turned spacers to hold the cube,; worked like a charm.

Round the edges/corners using the shadow technique, sand and finish. At this stage, finish the cube with whatever finishing you prefer, sanding sealer, polyurethane etc.

To make the top and bottom the finials, Garry started with 20mm doweling, used as a contrasting colour to the kauri. He suggested the top finial at 80mm and the bottom 100mm. Turn the finials to any shape you like, leaving a 7mm tenon and a 45deg base to fit the counter sunk recess left in the top and bottom of the cube. It was suggested from the floor that choosing a hard wood to make the finials would result in a better finish with less sanding required than the pine that Garry used.

Finish the decoration by adding a bell to the interior, or let your imagination and creative juices flow.

Well done Garry.

Club Meeting: 14 November 2018

Report by: Graeme Mackay

The efficient spinning top: String full driven and provided with actual measurements. Bruce’s demo was a spindle turning top based on the standard woodblock 70 mm x 70 mm x 180 mm. The wood is set between two centres before the attack. Bruce quickly changes the square into a cylinder with a measured spigot on the end.

Full of tips:

Tip 1: Watch the sharp tips on your Vernier callipers. Slightly rounded tips allow for a lot more safety on fingers.

Tip 2: When putting the chuck on, wind on with the headstock in until tight, then use the mechanisms provided.

Tip 3: There are lots of lovely tools for getting the dead centre. And, there is much ease in using a spring-loaded awl for making the mark.

Main body:

Planning is always an emphasis, starting with drilling a 4.5 mm whole on one end. The hole in this case was 40 mm long or twice the distance needed. Again the mantra of Bruce: measure. Then measure again. And then, check the plan.

The three part main body is measured off and worked, all the time being checked, for sealing and sanded. A good tidy with the skew chisel cuts down on sanding.

When the spin drive of the main body is completed, work on defining bead and following Cove for both looks and finish. The bottom section is tapered off slowly and the piece overall, believe it or not, conforms to Fibonacci.

Tip 4: Use the spindle gouge in an underhold style. This saves on fingers.

Tip 5: Sanding sealer cuts down the final effort and provides a good base for either the finishing lacquer or the Beale polishing system.

Turn the main piece around on the lathe and fit into pen jaws. This allows for the finishing of the pointy end. Care needs to be taken with the 4.5 mm hole at the end measurement. Again, to check that the final depth is correct.

Handle:

Bruce used wood 40 mm x 40 mm x 180 mm. Pre-drilling the holes for the top base and string outlets are best done when the wood is still square. The diameter of the straight round holes allow the fit of the top of the base top. The diameter of the oval holes allow for easy insert of string and the pulling to get the top going. These holes are in the top 1/8 of the length of this section. This section is kept square.

The rest of the handle is turned to make a good holding handle. Most of the work being done for looks rather than functional utility. It has to be said that Bruce’s beads and Cove sections make for a better looking handle.

Bruce tidy handiwork does get the beads and coves even and good-looking. In and turning language this means a lot of fiddly turning for finishing off. The edges of the square section are slightly rounded with gentle sanding. This removes most of the sharp edges.

String handle:

More turning between centres. A cylinder around 25 mm in diameter is tidied up, beaded and coved (looks) and gently sanded off for finish. Again, there is significant advantage in drilling the string hole while the piece is still square.

Tips 6: Drilling the hole on the square form for the string first is quite useful.

Tips 7: An initial dose of sanding sealer allows for a quicker and cleaner finishing and polishing.

Tip 8: Remember, a too heavy or too fast sanding with mechanical tools can leave a mark on the timber. Slowly and with soft hands avoids this issue.

There are many options for taking off the buds at each end of the string handle; penknife, small Japanese saw, power saw poor some form of mechanical sanding.

The nail on the base, one of the final steps, can be rounded off by holding it in a Jacobs chuck on the drive before insertion into the base body.

Then came the end bit:

The trial.

Yes.

It works!

Graeme Mackay

November 2018

Wednesday 16th November 2018

Report by: Bruce Wiseman

Our demonstrator, Janet McDonald, treated us to an evening of Creative Embellishment.

Janet is one of our new members, having been Wood turning only 6 months, hence she was not demonstrating turning, but the enhancement of items already turned.

She explained to us that she had been a hairdresser in 1999 and had subsequently written 7 books on Handcraft Art, including Mosaics.

With her craft work she told us she took a lesson out of Terry’s book and sold them for double the original asking price.

Out of her “Magic box” (no special wand like Dick,) came a number of decorated bowls and objects, which she had enhanced with paint and pyrography, some of which would have been suitable as Christmas decorations.

We were shown her style and method of Pyrography and the tool she used. The wire tips she made from Nichrome wire, bent so she could use it like a pen to draw or write with.

Patterns were traced onto the wooden object, then the tool used to burn into the wood.

Lunch wrap is ideal as a tracing paper. Use an old fine ball pen (no ink) as a tracing tool to transfer the pattern.

If transferring to a curved surface, scrunch up paper then spread over the item. This helps it to mould without deep creases.

Use designs from all sources, look outside the square.

When burning, relax, use light pressure. Wear Safety Glasses and clean the tip regularly to remove Carbon.

Set up a fan or similar airflow to draw fumes away – do not blow towards your work.

Janet used acrylic paint – test pots from Resene are good. The Metallic range is particularly ideal. Apply two base coats, then other colours as needed to produce the effect required.

Janet also showed us some gold and bronze leaf application, (use leaf not vinyl.)

She also demonstrated how to apply the size to where the leaf was to adhere, advising the use of gloves when painting on the size and allow 20 – 30 minutes for it to dry (tacky) before applying the leaf.

Embellishing tools are obtainable from Art Supply shops, E-Bay, or Terry’s Emporium.

Craft glue is available from Spotlight.

To finish with, a selection of decorated bowls, Christmas trees and Christmas puddings were passed around.

Thank you Janet for an unusual and interesting evening.